By utilizing the 2D drawings provided by the customer, we conduct the creation of 3D models and technical reviews. Precision requirements for the part are evaluated to determine the necessary manufacturing processes, tooling, and fixture production. This aims to enhance the feasibility of part production. If additional casting processes are required, we also need design drawings for machining, ensuring that they meet the customer's requirements and quotation.

After confirming the design of the mold model, reusable metal molds and sand cores can be produced. In the formal mold fabrication process, CAD is used to simulate the pouring of liquid metal during the casting process, ensuring the process and casting quality during mass production.

For the gravity casting molds at MingMing Aluminum, steel molds are used, and sand cores are made by mixing sand and thermosetting resin to shape the required holes and grooves inside the mold.

Once the metal molds and sand cores are made, samples are produced, and the entire production approval process is submitted to the customer for confirmation. LiJin can proceed to mass production after obtaining confirmation from the customer. The mold model ensures that the produced castings meet the required accuracy and can fit and assemble with other components. A small number of samples are produced using the mold model for customer confirmation, ensuring they meet requirements or making necessary design adjustments.

Once the metal molds and sand cores are made, samples are produced, and the entire production approval process is submitted to the customer for confirmation. LiJin can proceed to mass production after obtaining confirmation from the customer. The mold model ensures that the produced castings meet the required accuracy and can fit and assemble with other components. A small number of samples are produced using the mold model for customer confirmation, ensuring they meet requirements or making necessary design adjustments.

Effective management of production ensures a smooth production process, timely achievement of production plans, and compliance of products with standard quality. IPQC involves real-time inspection and monitoring of products during the manufacturing process, including sampling tests to ensure each product meets the predetermined quality standards. The integration of comprehensive quality standards and testing procedures, from raw material inspection to in-process sampling and final product comprehensive testing, ensures that production and IPQC complement each other. This combination of effective production management and real-time quality control guarantees high-quality products throughout the production process.

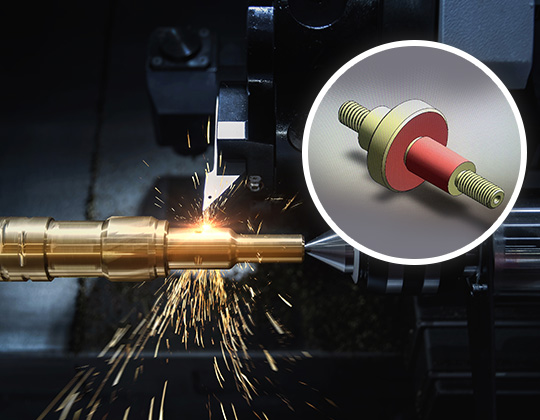

For the enhancement of product appearance, various treatments are applied, such as painting, coating, anodizing, etc., improving corrosion resistance, wear resistance, and aesthetics. Material treatment involves altering the physical and chemical properties of the product through methods like heat treatment, cold working, alloying, adjusting material hardness, strength, and elasticity to suit specific application environments and enhance overall product quality. Precision cutting and surface treatment using grinding wheels are employed to meet precision and smoothness requirements.

Upon completion of manufacturing, the finished products undergo OQC, including inspection of appearance, functionality, and performance, to ensure products meet customer needs and standards. Testing at different stages of the product life cycle ensures comprehensive quality control from manufacturing to shipment. After confirming the product's quality, arrangements for packaging and shipment are made.