Eliteprecision Maker Co., Ltd., firmly believes that accurate feasibility assessment is essential in the contract manufacturing industry. Only through this can we achieve a win-win situation with customers amidst commercial competition. Therefore, we regard two-way communication as the key element in the customization process. Through close technical communication with customers, we can understand their needs accurately, grasp cost control more precisely, and thus provide more competitive solutions. Eliteprecision Maker has always maintained good communication and cooperation with customers.

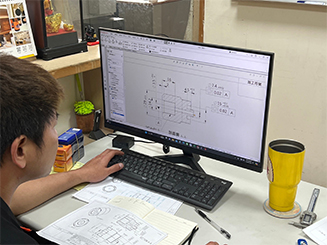

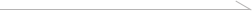

Initially, we receive drawings from customers, dismantle them, and create 3D and 2D drawings.

We confirm the relevant details of the workpiece processing with the customer and provide professional insights. This includes selecting materials (whether raw materials or castings), identifying potential issues during processing (such as unreasonable drawing aspects), and selecting materials and tools.

We use CAM software to simulate the machining process and assess whether fixtures are needed for assistance. If required, we proceed with fixture design and drawing.

Eliteprecision Maker's cost control method is based on information provided by existing suppliers and manufacturing processes for quotation. Initially, we produce samples and small batches according to the existing process, then discuss cost issues with customers. If customers find the price of the workpiece lacking competitiveness, we will discuss cost reduction from the perspective of raw materials, such as process optimization to improve cost-effectiveness, to meet customer expectations.

Eliteprecision Maker's quality control (QC) process is rigorous. We formulate quality inspection sheets based on drawings to ensure product compliance. After small batch production, we use the Cpk value generated during the manufacturing process to improve and prevent potential issues in subsequent mass production. Cpk observation is conducted for each order to assess production stability. Additionally, Eliteprecision Maker conducts Ppk evaluations, and after obtaining relatively stable values, begins formulating inspection methods based on ISO2859-1974 and ISO3951-1981 to ensure long-term stability.

Eliteprecision Maker adheres to proactive evaluation, two-way communication, and rigorous quality control. We understand customer needs accurately, provide more competitive solutions through process optimization and cost-benefit analysis. Eliteprecision Maker will continue to strive to provide high-quality, high-efficiency manufacturing solutions and achieve long-term stable partnerships.